Call Us Now

TEL: +86 13386078659; Skype ID: Hanwei; WeChat: +8613386078659; QQ ID: 413882258.

Item No.:

TR4000S-600Payment:

FOBProduct origin:

ChinaColor:

BlueShipping port:

ShangHaiLead Time:

28

First, Design parameters

1. Material temperature: no more than 80 ℃

2. Equipment material: conveyor belt material POM,frame is stainless steel.

3. Material delivery time; about 30 minutes

4. Conveying speed: 0--2m / min

5. Material delivery volume: 1.2T / h

6. Conveyor belt width: 600mm

7. Import height: 1000m (50mm adjustable); Export height: 4000mm

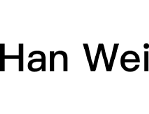

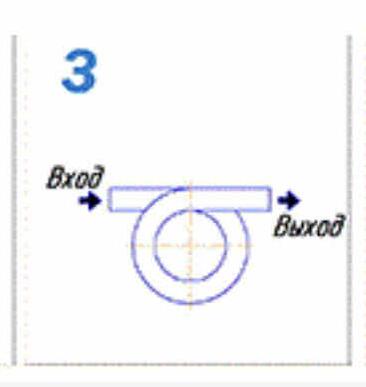

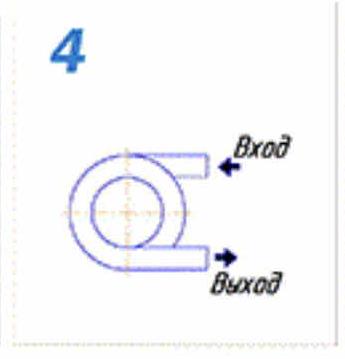

The direction of input and output as shown blow:

8. Conveyor belt is about 80 meters, 1000 mm length of input,2500 mm length of output!

9. Installation location: indoor

10. Power supply: The buyer needs to provide a 380vpower supply to the equipment, and the total power is set to 3.7KW.

11. The main motor power is 2.2 kW, and theauxiliary motor is 1.5 kW. The motor brand is Cheng Bang, and the reducer isfrom Delta.

12. Equipment size: height 4200mm * diameter 3500mm

Second, TechnicalRequirement

1. The spiral cooling tower adopts the form ofbottom-in and top-out, and the required installation position of the bottommotor. The overall dimensions of the equipment are subject to the conditiondiagram, and the manufacturer can make fine adjustments.

2. The conveyor belt adopts the form of networkchain and POM material

3. The conveyor belt is tentatively scheduled for 7layers, with a layer height of approximately 420mm.

4. The net chain is made of stainless steel, thenet surface is smooth, and the chain piece and the shaft are connected tooperate flexibly.

5. The equipment is equipped with a frequencyconversion control system with adjustable speed.

6. All equipment should be properly designed andmanufactured to meet the requirements of safe and continuous operation underall working conditions. All equipment parts adopt advanced and reliableprocessing and manufacturing technology.

7. Direction of movement: Enter from the bottom andoutput from the top.

Third, Equipmentconstruction content

1. Main structural features, components andtechnical description of the spiral tower:

1. Adopt the main reducer to drive the auxiliaryreducer to tighten and automatically adjust the tightness of the mesh belt, sothat the mesh belt runs under a low-loss state.

1) Overall frame structure:

a) The overall frame structure, support, supportrails, transmission shaft, frame, mesh belt and other components are made ofstainless steel;

b) The inner and outer supporting rails aredesigned to support the spiral mesh belt under the spiral mesh belt to ensurethe reliability of the spiral mesh belt. The ultra-high molecular polyethylenematerial is embedded on the supporting strip, which greatly reduces thefriction coefficient with the mesh belt. Ensure stable operation of equipment;

c) The rotating hub adopts a squirrel cagestructure, and the vertical bar of the rotating hub is embedded with anultra-high molecular polyethylene sheath, which makes the rotating hub morecompliant and smooth when contacting and separating from the mesh belt.

d) The guide wheel is made of nylon 1010;

2) Drive device:

a. The driving device adopts high-qualityhard-tooth surface helical gear reducer, and the gear meshing surface hashigh-precision machining and heat treatment process.

b. Helical gear reducer is a special technologyshaft sealing device, which avoids the leakage of lubricating oil and ensuresthe requirements of food hygiene.

c. In order to ensure the accuracy of the chaindrive, the entire drum sprocket manufacturing process is used. The auxiliaryreducer and the main reducer operate relatively synchronously and the spiralmesh belt is driven smoothly by the mesh belt traction sprocket.

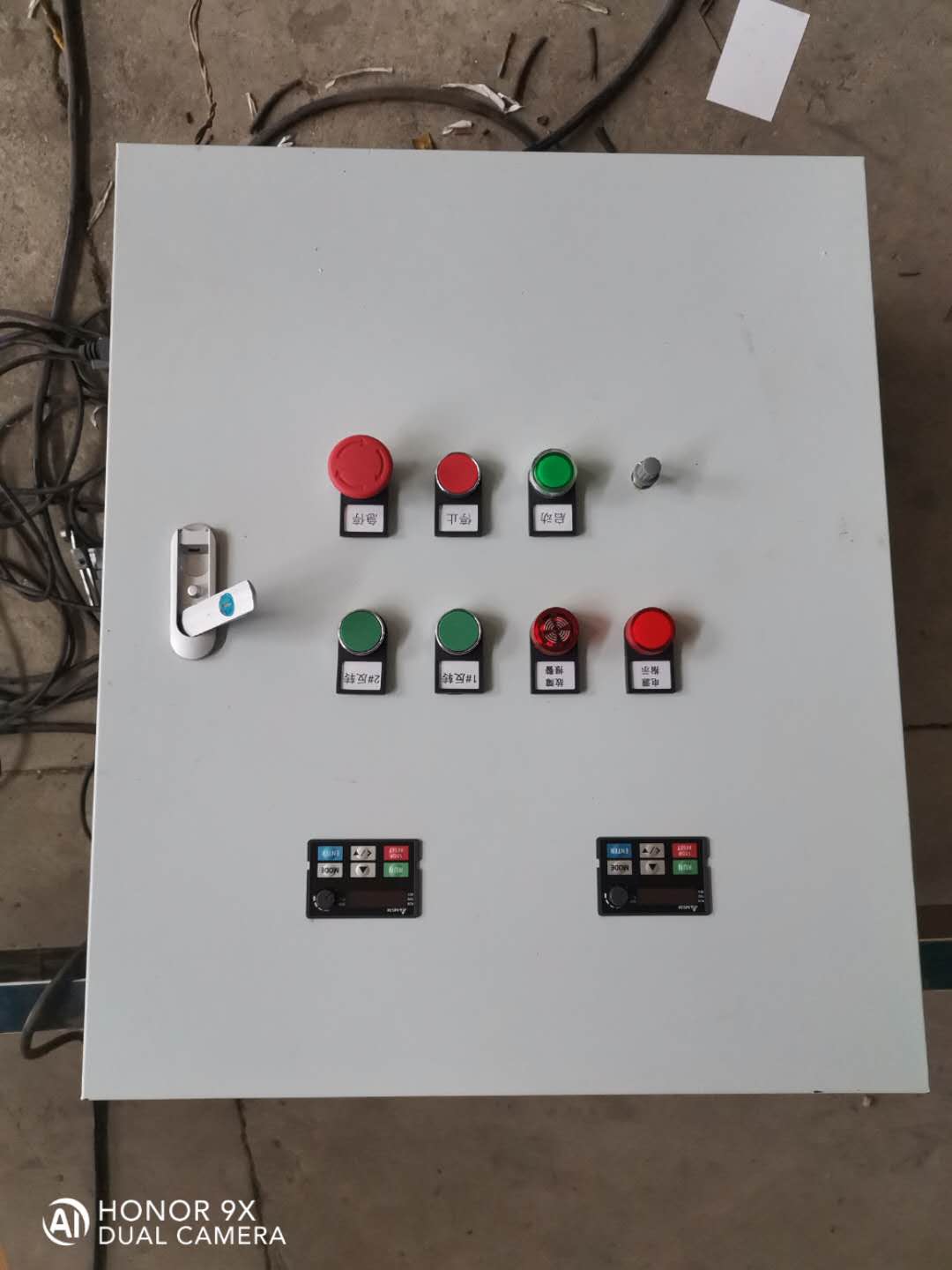

3) Electronic control part:

4) The professional electric box is made ofmoisture-proof and dust-proof stainless steel electric control box. Theelectric box is equipped with a cooling fan and PVC inlet and outlet windprotection net cover, which has good dustproof and waterproof effect.

Design Specification for Spiral Cooling Tower 2

First. Design parameters

1. Material temperature: no more than 80 ℃

2. Equipment material: conveyor belt material POM,frame is stainless steel.

3. Material delivery time; about 50 minutes

4. Conveying speed: 0--2m / min

5. Material delivery volume: 2T / h

6. Width of conveyor belt: 300mm

7. Import height: 800mm, export height 2950m

8. Conveyor belt is about 180 meters

9. Installation location: indoor

10. Power supply: The buyer needs to provide a 380vpower supply to the equipment, and the total power is set to 3.7KW.

11. The main motor power is 2.2 kW, and theauxiliary motor is 1.5 kW. The motor brand is Chengbang, and the reducer isfrom Delta.

12. Equipment size: height 3200mm * diameter 3100mm

Second. Technical requirements

1. The spiralcooling tower adopts the form of bottom-in and top-out, and the requiredinstallation position of the bottom motor. The overall dimensions of theequipment are subject to the condition diagram, and the manufacturer can makefine adjustments.

2. The conveyorbelt adopts the form of network chain and POM material

3. The conveyorbelt is tentatively set at 13 layers with a layer height of approximately190mm.

4. The net chainis made of stainless steel, the net surface is smooth, and the chain piece andthe shaft are connected to operate flexibly.

5. The equipmentis equipped with a frequency conversion control system with adjustable speed.

6. All equipmentshould be properly designed and manufactured to meet the requirements of safeand continuous operation under all working conditions. All equipment partsadopt advanced and reliable processing and manufacturing technology.

Third. Equipment construction content

1. Mainstructural features, components and technical description of the spiral tower:

1. Adopt themain reducer to drive the auxiliary reducer to tighten and automatically adjustthe tightness of the mesh belt, so that the mesh belt runs under a low-lossstate.

1) Overall framestructure:

a) The overallframe structure, support, support rails, transmission shaft, frame, mesh beltand other components are made of stainless steel;

b) The inner andouter supporting rails are designed to support the spiral mesh belt under thespiral mesh belt to ensure the reliability of the spiral mesh belt. Theultra-high molecular polyethylene material is embedded on the supporting strip,which greatly reduces the friction coefficient with the mesh belt. Ensurestable operation of equipment;

c) The rotatinghub adopts a squirrel cage structure, and the vertical bar of the rotating hubis embedded with an ultra-high molecular polyethylene sheath, which makes therotating hub more compliant and smooth when contacting and separating from themesh belt.

d) The guidewheel is made of nylon 1010;

2. Drive unit:

a. The drivingdevice adopts high-quality hard-tooth surface helical gear reducer, and thegear meshing surface has high precision machining and heat treatment process.

b. Helical gearreducer is a special technology shaft sealing device, which avoids the leakageof lubricating oil and ensures the requirements of food hygiene.

c. In order toensure the accuracy of the chain drive, the entire drum sprocket manufacturingprocess is used. The auxiliary reducer and the main reducer operate relativelysynchronously and the spiral mesh belt is driven smoothly by the mesh belttraction sprocket.

1) Electroniccontrol part:

2) Theprofessional electric box is made of moisture-proof and dust-proof stainlesssteel electric control box. The electric box is equipped with a cooling fan andPVC inlet and outlet wind protection net cover, which has good dustproof andwaterproof effect.

Online service

Online service +86 13386078659

+86 13386078659 ysb189@163.com

ysb189@163.com yusb@shhanwei.cn

yusb@shhanwei.cn hanwei@shhanwei.cn

hanwei@shhanwei.cn Hanwei

Hanwei Hanwei

Hanwei 413882258

413882258 +8613386078659

+8613386078659