Call Us Now

TEL: +86 13386078659; Skype ID: Hanwei; WeChat: +8613386078659; QQ ID: 413882258.

Item No.:

PEAK-FM-200Payment:

FOBProduct origin:

ChinaColor:

Shipping port:

ShangHaiLead Time:

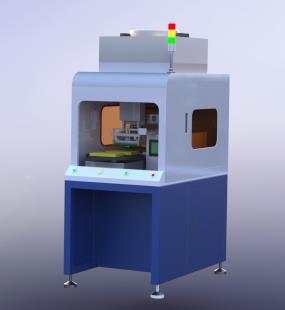

15Automaticcoating machine (PEAK-FM-200)

Basic instructions

1-1. Name & Model Name:Automatic filming machine

Model:PEAK-FM-200

1-2.The purpose of the device

This automatic coating machine can be applied to glass, light guideboard, touch paneland other industries of the coating process. All requirements for preciseposition requirements can be used.

1-3.Characteristics

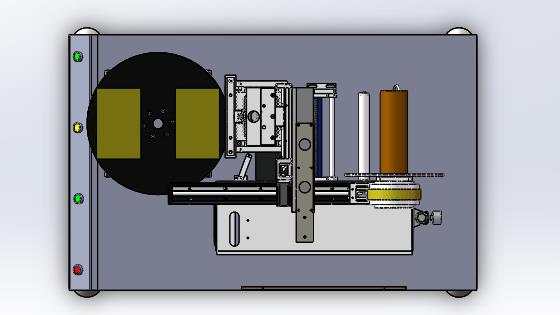

1. The whole machine consists of X-axis, Y-axis and membrane shaft.

2. Place theglass manually. On the coating countertop, the positioning sheet or positioningpin is used to secure the glassfirst. Theplatform has vacuum. Holes to produce suction. Place the glass and press therotation key, the platform rotates, waiting for the coating.

3. When theautomatic key is pressed, Step 2 The action of releasing glass is carried out at the same time as theaction of automatic membrane discharge. The membrane-out mechanism automaticallyfilms out of the membrane at the length set on the HMI interface. Eachtime the coating is finished, another film is automatically created.

4. After the filmis finished, the positioning mechanism will go in for the positioning of theY-axis. The positioning mechanism has 1 fiber, which isused first to locate the edges in the Y direction;

5. The devicepositions the Y-axisdirection before pressing the coating button. Then make up in thedirection of the Y-axis. If the setting value is greater than 0, the Y-axis direction compensation is made. The setdistance in the direction of the Y-axis. Afterthe Y direction positioning is complete, then the X-axis orientation positioning is carried out. Leave the fiber position first, and thenposition the X direction.

6. After theX-axis orientation positioning is complete, if the platform is transferred to the correct position, the coatingmechanism will go to the set position and start the coating.

7. After thecoating is complete,the X-Y axis returns to its original position andbegins the next coating.

8. With thehigh-performance Panasonic FP-X Series PLCinJapan, it ishighly automated and integrated, reducing commissioning time and error-proofing. Theoperator interface uses a color touch man-machine interface. With 10 setsof operating mode memory addresses, it is easy to remember at the touch of a fewswitches and call up the set mode.

9. Equipped withother safety protection: error indication,automatic error prevention, emergency stop button, security protection.

1-4. Specification parameters:

Specifications | |

size (mm) | 1360 (W) * 840(L) *1600 (H) |

Weight(Kg) | 210Kg |

Environmental requirements | Reserved space: Leave at least 700 mm of space at the front of the machine. |

Glass size(mm) | Length:50-200(Adjustable according to customer requirements) |

Cycle time | 4.5S/PCS |

Accuracy | ±0.1mm |

How to calibrate | X/Y Axis Paramethration Correction |

System control | PLC and human-machine interface |

Power. | 220V 2KW |

1-5.Machineconfiguration

Name | Brand | Origin |

Servo motor | Panasonic | Japan |

Servo motor driver | Panasonic | Japan |

Fiber optic sensors | Omron | Japan |

Cylinder | SMC | Japan |

PLC | Panasonic | Japan |

Screw | Hiwin | Taiwan, China |

Rotating work table | Misumi | Japan |

Touch screen | Teda. | Taiwan, China |

Thousand-stage high-efficiency dust removal device (optional). | Futai | China |

Online service

Online service +86 13386078659

+86 13386078659 ysb189@163.com

ysb189@163.com yusb@shhanwei.cn

yusb@shhanwei.cn hanwei@shhanwei.cn

hanwei@shhanwei.cn Hanwei

Hanwei Hanwei

Hanwei 413882258

413882258 +8613386078659

+8613386078659