Call Us Now

TEL: +86 13386078659; Skype ID: Hanwei; WeChat: +8613386078659; QQ ID: 413882258.

Item No.:

TR1200/1600-MBMPayment:

FOBProduct origin:

ChinaColor:

Orange & WhiteShipping port:

ShangHaiLead Time:

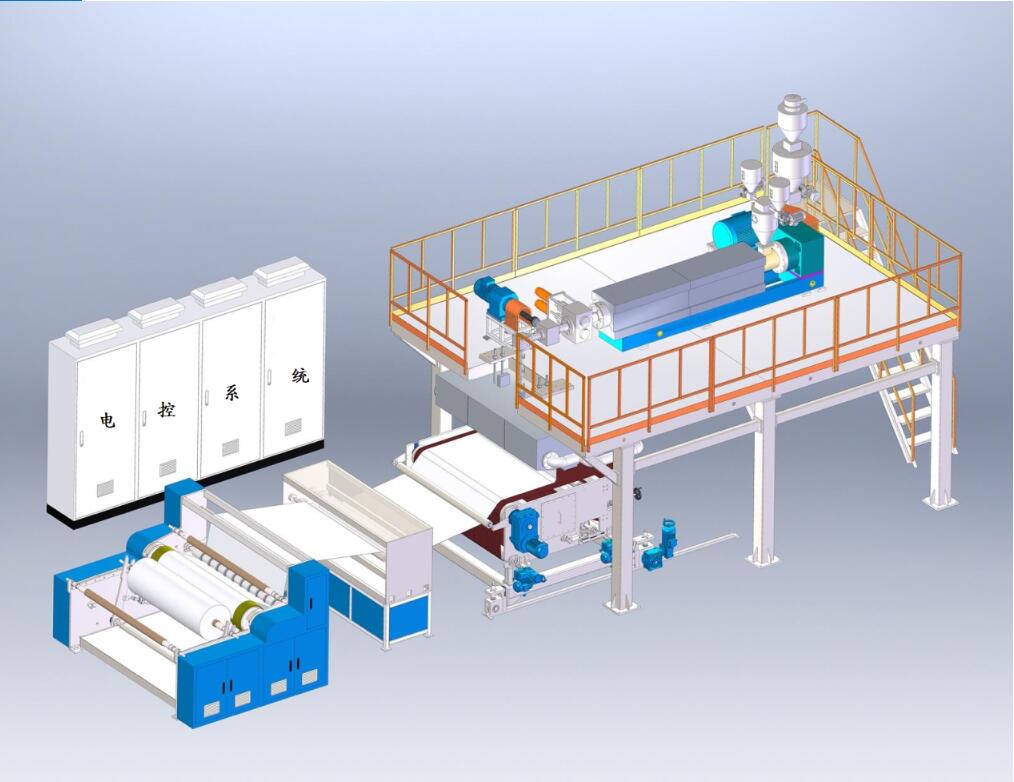

28Melt blownfabric production lines

9600-1600mmSingle-Mold melt-blown technology configuration

I, Overview: | |

This equipment uses polypropylene melt blown raw materials as the main raw materials, supplemented by additives such as electrostatic auxiliary master batch or color master batch, to produce polypropylene melt blown nonwoven fabrics with different colors, different properties and suitable for different uses. | |

1. Conditions of use | 380V/50Hz |

2. Product application | Melt blown filter materials, mask filter materials |

3. Materials used | Polypropylene chip raw materials (special materials for melt blowing) MFI=1200~1800 g/min Recommended 1500g/min |

4. Product width | 1600mm |

5. Product weight range | 25-80g/m2 |

6. Extrusion ability | 1–1.5 tons/24 hours (As the product weight changes, the production line capacity changes accordingly) |

7. Maximum mechanical speed | 0-50m/min |

8. Fiber fineness | 2-5μm |

9. Installed power | About 560KW |

II, Equipment list | |

1. Automatic feeding device | 1 set |

2. Screw extruder | 1 set |

3. Screen changer | 1 set |

4. Metering pump | 1 set |

5. Melt pipeline | 1 set |

6. Combined melt blown die head | 1 set |

7. Process hot air system | 1 set |

8. Air heater | 1 set |

9. Suction fan | 1 set |

10. Connect the air duct | 1 set |

11. Net forming machine | 1 set |

12. Electret processing system | 1 set |

13. Winder | 1 set |

14. Electrical control system | 1 set |

III, Detailed technical configuration | |

1. Automatic batching and feeding device | |

Raw material temperature | All raw materials are below 80 degrees |

Raw material properties | All raw materials are granular |

Installation location | Above the discharge opening of the extruder |

Matching ability | Component 1: 100% Component 2: 1~50% Component 3: 0.5~3% |

Vacuum feeding system | 1 set |

2. Screw extruder | |

Screw barrel | |

Material | 38CrMoAl |

Nit riding depth | 0.5-0.7mm |

Screw hardness | HV>=740 |

Barrel hardness | HV>=940 |

Aspect ratio L/D | 30:1 |

Screw diameter | 90mm |

Barrel heating area | District 5 |

Total heating power | About 35KW |

way to heat up | Cast aluminum heating |

Transmission | |

Motor | AC motor |

Motor Power | 45KW |

Reducer | |

Cabinet material | QT200 |

Gear form | helical gear |

Gear material | 20CrMnTi |

Gear surface heat treatment | Tooth surface quenching |

Thrust bearings | Domestic high-quality bearings |

Lubrication system | Pressure lubrication system |

cooling system | Internal cooling and forced circulation cooling |

Rotating speed | 20-80r/min |

Insulation cover outside the barrel | |

3 、Net changer | |

structure type | Double station column type net changer |

Screen change driver | Hydraulic system drive, manual control |

way to heat up | Built-in heating rod heating |

Temperature measurement | K type thermocouple |

Pressure Sensor | Equipped with a pressure sensor in front of the net changer to display the pressure of the extruder |

4、Metering pumps | |

Specification | 120CC |

motor | Frequency conversion motor |

speed control | Frequency converter |

Drive motor power | 3 KW |

way to heat up | Built-in stainless steel heating rod for heating |

Pressure measurement | The melt metering pump is equipped with a pressure sensor in front of it to control the speed of the extruder to maintain the stability of the extrusion volume; the metering pump is equipped with a pressure sensor to display the output pressure |

5 、Melt pipe | |

Material | Seamless stainless steel pipe |

Way to heat up | Heating with heating ring |

6 、Combined melt blown die head and spinneret | |

Total length of phantom | 1940mm |

Effective discharge length of die head | 1702mm |

heating power | Around 16KW |

Spindle hole diameter | 0.20-0.30mm |

Spindle hole length to diameter ratio | 10:1 |

Number of spinnerets | 1 set |

The spinneret transforms the solution into a fine stream, which is formed into ultra-fine fibers after being drawn by a high-temperature high-speed air stream | |

7 、Process hot air system | |

Roots blower model | 3L53WC |

Boost | 70Kpa |

Import flow | 38.3m3/min |

power | 75KW |

Roots blower | Provide high-pressure air to make the speed of drafting air reach the technological requirements |

Through the frequency converter, the air flow output by the Roots blower can be easily changed through the inverter. | |

8 、Air heater | |

heating power | 230KW |

Material of pipeline | stainless steel |

Insulation form | Outsourcing insulation |

Air heating tank | Heat the air output from the Roots blower to reach the temperature required by the process |

9 、Suction fan | |

Suction air volume | 17000-30000m3/min |

Wind pressure | 3KPa |

power | 55KW |

10 、Connect duct | |

Material | Galvanized air duct |

11 、 Net forming machine | |

Line speed | 0-50m/min |

Net curtain material | PA material |

Mesh belt width | 1500mm |

Spinning distance adjustment | 80-300mm |

Installation form | Horizontal movement |

Drive rate | 5.5KW |

12 、Electret processing equipment | |

Input voltage | 220V/50HZ |

Maximum output voltage | 80KV |

Processing width | 1300mm |

13 、Winder | |

Line speed | 0-50m/min |

Trimming device | 8 round tools |

transmission | Motor |

Power | 7.5KW |

Shafts | Paper tube core 3 inches |

14 、Electrical control system | |

Operation screen | Siemens Brand |

PLC | Siemens Brand |

Frequency converter | ABB brand |

Contactor | Siemens Brand |

Relay | Omron brand |

Low voltage circuit breaker | ABB or LS, Chint brand |

air switch | Schneider or ABB, LS brand |

Button and switch indicator | Schneider |

Online service

Online service +86 13386078659

+86 13386078659 ysb189@163.com

ysb189@163.com yusb@shhanwei.cn

yusb@shhanwei.cn hanwei@shhanwei.cn

hanwei@shhanwei.cn Hanwei

Hanwei Hanwei

Hanwei 413882258

413882258 +8613386078659

+8613386078659